Many businesses are especially keen on the quality of their products and services. This isn’t a surprise when the quality of how goods are being made and how services are being done will reflect the business’s image. This is one of the reasons why many organizations will emphasize quality assurance and control.

However, placing too much emphasis on the quality of the product means that manufacturing costs can significantly increase. Although there’s no problem in maximizing the quality of goods and services, it’s still crucial to keep a balance of quality and conserving resources that can be used for other aspects of the business.

So what are some ways of cutting down on manufacturing costs without sacrificing the quality of the product? What are some factors that you will need to consider? Here’s what you need to know.

Cutting Down on Material Costs

One of the simplest ways of cutting down on manufacturing costs and saving more money than usual is by directly addressing material costs and cutting down on what’s needed for specific manufacturing processes.

Contrary to what most people think, you won’t have to sacrifice the quality of the product, which can cause problems with sales and revenue. Many companies can cut down the materials used for production while maintaining the same quality through various ways, such as tweaking the product’s design.

Through careful research and development, all the resources used to design products can be maximized for the best possible result. This is especially true for many tech companies that are constantly changing how smartphones are being produced to cut material costs without sacrificing any features of smartphones.

Many experts suggest choosing a simpler and more minimalist design for products since this can help save raw materials. In most cases, packaging will take a good chunk of these materials. You might find some use in cardboard boxes, paper, and metal leftovers in your working environment that can be used for your products. Not only will this help cut down on spending for materials, but this can significantly increase the number of products that these materials can produce at a specific timeframe.

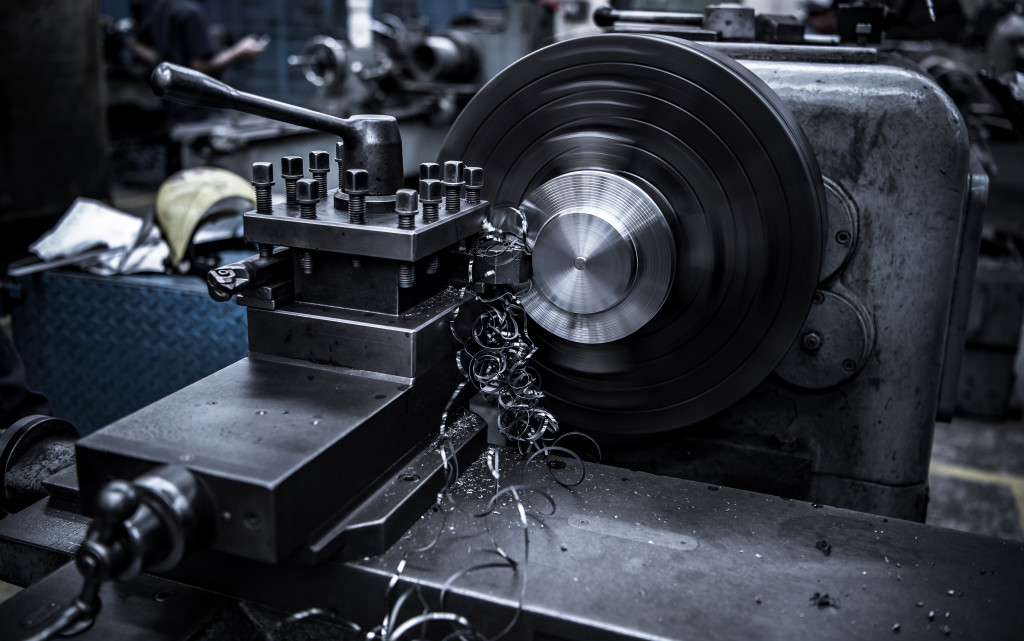

Automating the Process with the Right Equipment

Hundreds of companies are looking for ways to have a clear advantage over other companies. Since competition can be intense between different manufacturers, you must get an advantage by streamlining the process. Automating the process is one of the best ways of gaining an advantage over other manufacturers.

Perhaps one of the most critical parts of cutting down on the manufacturing cost of products is through the automation process. This has been one of the most effective ways of cutting downtime, energy, and manual labor needed to create materials.

However, it’s essential to consider that even though automating the process can help with your equipment, manual supervision from workers is still needed to ensure that products are in good condition.

Still, you will need to keep in mind that different types of equipment are used for various industries. Automated machinery used to produce edible products is different from machinery used in manufacturing electronics. If you’re in the food and beverage industry, you might want to consider using equipment that can help minimize raw materials wasted to produce the best results for your products. Fortunately, you won’t have to look far since quality piston depositor equipment can help cut down on material wastes while also saving costs for the manufacturing process.

Placing Emphasis on the Workforce

Although you might be placing emphasis and investing in newer state-of-the-art equipment, the workforce is the beating heart of your daily operations. If you want to ensure a steady pace of work being done, invest in the right programs for your employees.

Automation can help expedite the working process. However, you will also need to train your employees. Improving their skills is an excellent way of significantly improving their productivity. Many qualified employees can help with the cost of labor and materials wasted during the manufacturing process.

Reaching Out to Material Manufacturers

You need to reach out to the manufacturers of these raw materials. Building trust and a long-term relationship with your suppliers and component manufacturers can give you an edge over your competitors, especially when they give you lower prices. But right before you attempt any form of negotiation, ensure that you’ve done your side of the deal. If you’ve already been a dependable partner for these suppliers, you can offer them a deal that can benefit both parties and reach a reasonable reduction of prices.

Various tried-and-tested strategies can help cut down on the cost of manufacturing products. If you want to make more than usual, take on risks, especially investments. Not only will you need to invest in the proper equipment, but you should also invest in your workforce. Even though you might have to spend more in the short term, you will eventually benefit in the long run.

Still, you need to be aware that there’s no one “ultimate” way of cutting down on the cost of manufacturing. It’s best to be cautious when you’re cutting down on manufacturing costs since this can affect the quality of your product. Whatever the situation may be, being methodical with your approach can yield the best results.